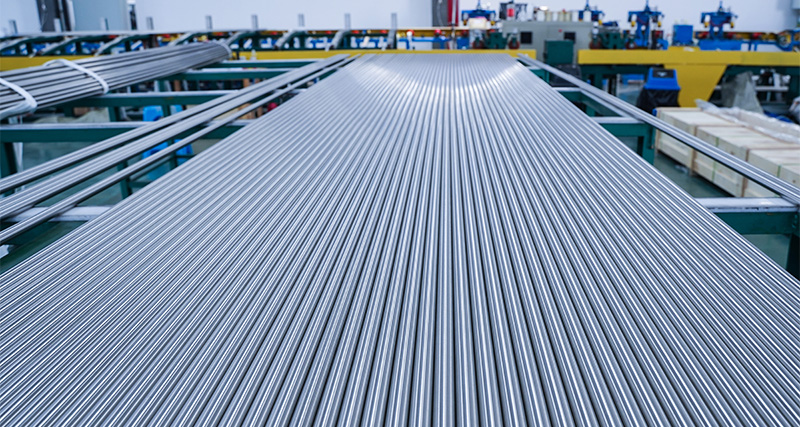

Tuubo Bilicsan oo aan kala go 'lahayn (BA)

Sharaxaadda Badeecada

Biyo-qaboojinta dhalaalaya waa hab lagu buufiyo oo lagu sameeyo meel faakuum ah ama jawi la xakameeyey oo ay ku jiraan gaasas aan firfircoonayn (sida haydarojiin). Jawigan la xakameeyey wuxuu yareeyaa oksaydhka dusha sare taasoo keenta dusha sare oo dhalaalaysa iyo lakab oksaydh oo aad u khafiifsan. Biyo-shiidka looma baahna ka dib biyo-shiididda dhalaalaya maadaama oksaydhku uu yar yahay. Maadaama uusan jirin wax biqil ah, dusha sare aad ayuu u siman yahay taasoo keenta iska caabin wanaagsan oo ka dhan ah miridhka.

Daawaynta dhalaalaya waxay ilaalisaa simanka dusha sare ee la duubay, dusha sare ee dhalaalayana waxaa la heli karaa iyada oo aan la farsamayn ka dib. Ka dib marka la nadiifiyo dhalaalaya, dusha sare ee tuubada birta ah waxay ilaalisaa dhalaalka birta asalka ah, waxaana la helay dusha sare ee dhalaalaya oo u dhow dusha muraayadda. Shuruudaha guud, dusha sare waxaa si toos ah loogu isticmaali karaa iyada oo aan la farsamayn.

Si buufinta dhalaalaysa ay waxtar u yeelato, waxaan nadiifinnaa oogada tuubada ka ilaalinnaa walxo qalaad ka hor inta aan la buufin. Waxaanna ka ilaalinnaa jawiga buufinta foornada inay ka xorowdo ogsijiin (haddii natiijo dhalaalaya la rabo). Tan waxaa lagu gaaraa iyadoo laga saarayo ku dhawaad dhammaan gaaska (abuurista faakiyuum) ama iyadoo la beddelayo ogsijiinta iyo nitrogen iyadoo la adeegsanayo haydarojiin ama argon qalalan.

Nadiifinta iftiinka leh ee faakuumka waxay soo saartaa tuubo aad u nadiif ah. Tuubadani waxay buuxisaa shuruudaha khadadka sahayda gaaska ee aadka u sarreeya sida simanka gudaha, nadaafadda, iska caabbinta daxalka oo la hagaajiyay iyo hoos u dhaca gaaska iyo qiiqa walxaha ka soo baxa birta.

Badeecadaha waxaa loo isticmaalaa qalabka saxda ah, qalabka caafimaadka, dhuumaha warshadaha semiconductor-ka ee saafiga sare leh, dhuumaha baabuurta, dhuumaha gaaska shaybaarka, silsiladda warshadaha hawada sare iyo haydarojiin (cadaadis hoose, cadaadis dhexdhexaad ah, cadaadis sare) tuubooyin bir ah oo aan lahayn cadaadis aad u sarreeya (UHP) iyo goobo kale.

Waxaan sidoo kale haynaa in ka badan 100,000 mitir oo kayd ah oo tuubooyin ah, kuwaas oo macaamiisha la kulmi kara waqtiyada keenista degdegga ah.

Heerka Agabka

| Qaramada Midoobay | ASTM | EN |

| S30400/S30403 | 304/304L | 1.4301/1.4307 |

| S31603 | 316L | 1.4404 |

| S31635 | 316Ti | 1.4571 |

| S32100 | 321 | 1.4541 |

| S34700 | 347 | 1.4550 |

| S31008 | 310S | 1.4845 |

| N08904 | 904L | 1.4539 |

| S32750 | 1.441 | |

| S31803 | 1.4462 | |

| S32205 | 1.4462 |

Faahfaahinta

ASTM A213 /ASTM A269/ASTM A789/EN10216-5 TC1 ama sida waafaqsan shuruudaha.

Adkaanta & Adkaanta

| Heerka Wax Soo Saarka | Qalafsanaanta Gudaha | Dusha sare ee OD | Adkaanta ugu badan | ||

| Nooca 1aad | Nooca 2aad | Nooca 3aad | Nooca | HRB | |

| ASTM A269 | Ra ≤ 0.35μm | Ra ≤ 0.6μm | Codsi ma jiro | Polish farsamo | 90 |

Geedi socodka

Rogidda qabow / Sawir qabow / Qabow.

Baakad

Tuubo kasta oo keliya ayaa labada darafba ku xiran, oo lagu duubay lakab nadiif ah oo bacaha ah, ugu dambayntiina waxaa lagu riday kiis alwaax ah.

Codsiga

Kiimikada iyo batroolka/ Awoodda iyo tamarta/ Soo-saarka beddelaha kulaylka/ Nidaamyada Haydarooliga iyo farsamada/ Nadiifinta gaaska

Shahaadada Sharafta

Heerka ISO9001/2015

Heerka ISO 45001/2018

Shahaadada PED

Shahaadada imtixaanka iswaafajinta haydarojiin ee TUV

Su'aalaha Badiya La Weydiiyo

- Buuxinta Buuxda.

- Qaboojinta kuleylka ee Isothermal-ka.

- Buuxinta aan dhammaystirnayn.

- Kala-goynta Kala-goynta.

- Faafinta, ama Isku-darka, Qaboojinta.

- Joojinta Walbahaarka.

- Dib-u-warshadaynta Qaboojinta.

Qaboojinta waa hab lagu daweeyo kulaylka kaas oo beddela sifooyinka jireed iyo mararka qaarkoodna sidoo kale kiimikada ee walaxda si loo kordhiyo isku-xidhnaanta loona yareeyo adkaanta si looga dhigo mid la shaqayn karo. Habka qaboojinta waxay u baahan tahay walaxda ka sarraysa heerkulka dib-u-cusboonaysiinta muddo go'an ka hor inta aan la qaboojin.

Qaboojinta waa hab lagu daweeyo kulaylka oo loo isticmaalo in lagu beddelo sifooyinka biraha iyo walxaha kale, si caadi ah looga dhigo kuwo jilicsan, dabacsan, oo aan jabnayn. Waxay ku lug leedahay kululaynta walxaha heerkul gaar ah ka dibna si tartiib tartiib ah loogu qaboojiyo si la xakameeyey, si loo maareeyo qaab-dhismeedka kristalinta.

| Maya. | Cabbirka (mm) | Cabbirka Tuubada EP (316L) Waxaa xusay ● | |

| OD | Thk | ||

| Tuubada BA ee gudaha qallafsanaanta dusha sare ee Ra0.35 | |||

| 1/4" | 6.35 | 0.89 | ● |

| 6.35 | 1.00 | ● | |

| 3/8" | 9.53 | 0.89 | ● |

| 9.53 | 1.00 | ||

| 1/2” | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ● | |

| 3/4” | 19.05 | 1.65 | ● |

| 1 | 25.40 | 1.65 | ● |

| Tuubada BA ee gudaha qallafsanaanta dusha sare Ra0.6 | |||

| 1/8" | 3.175 | 0.71 | |

| 1/4" | 6.35 | 0.89 | |

| 3/8" | 9.53 | 0.89 | |

| 9.53 | 1.00 | ||

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 9.53 | 3.18 | ||

| 1/2" | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 5/8" | 15.88 | 1.24 | |

| 15.88 | 1.65 | ||

| 3/4" | 19.05 | 1.24 | |

| 19.05 | 1.65 | ||

| 19.05 | 2.11 | ||

| 1" | 25.40 | 1.24 | |

| 25.40 | 1.65 | ||

| 25.40 | 2.11 | ||

| 1-1/4" | 31.75 | 1.65 | ● |

| 1-1/2" | 38.10 | 1.65 | ● |

| 2" | 50.80 | 1.65 | ● |

| 10A | 17.30 | 1.20 | ● |

| 15A | 21.70 | 1.65 | ● |

| 20A | 27.20 | 1.65 | ● |

| 25A | 34.00 | 1.65 | ● |

| 32A | 42.70 | 1.65 | ● |

| 40A | 48.60 | 1.65 | ● |

| 50A | 60.50 | 1.65 | |

| 8.00 | 1.00 | ||

| 8.00 | 1.50 | ||

| 10.00 | 1.00 | ||

| 10.00 | 1.50 | ||

| 10.00 | 2.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||

| 12.00 | 2.00 | ||

| 14.00 | 1.00 | ||

| 14.00 | 1.50 | ||

| 14.00 | 2.00 | ||

| 15.00 | 1.00 | ||

| 15.00 | 1.50 | ||

| 15.00 | 2.00 | ||

| 16.00 | 1.00 | ||

| 16.00 | 1.50 | ||

| 16.00 | 2.00 | ||

| 18.00 | 1.00 | ||

| 18.00 | 1.50 | ||

| 18.00 | 2.00 | ||

| 19.00 | 1.50 | ||

| 19.00 | 2.00 | ||

| 20.00 | 1.50 | ||

| 20.00 | 2.00 | ||

| 22.00 | 1.50 | ||

| 22.00 | 2.00 | ||

| 25.00 | 2.00 | ||

| 28.00 | 1.50 | ||

| BA Tube, Ma jiraan wax codsi ah oo ku saabsan qallafsanaanta dusha sare ee gudaha | |||

| 1/4" | 6.35 | 0.89 | |

| 6.35 | 1.24 | ||

| 6.35 | 1.65 | ||

| 3/8" | 9.53 | 0.89 | |

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 1/2" | 12.70 | 0.89 | |

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 6.00 | 1.00 | ||

| 8.00 | 1.00 | ||

| 10.00 | 1.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||